ENTROPIC™ SUSTAINABLE MATERIALS

PLA-based Compostable Compounds

Entropic™ Sustainable Materials has developed PLA-based Compostable Compounds to improve heat resistance and degradation kinetics when compared to standard PLA. This falls in line with Interfacial Consultants' mission to preserve our environment through the creation of deliberate design materials that maintain high functionality while rapidly and harmlessly degrading in the environment.

Applications & Uses:

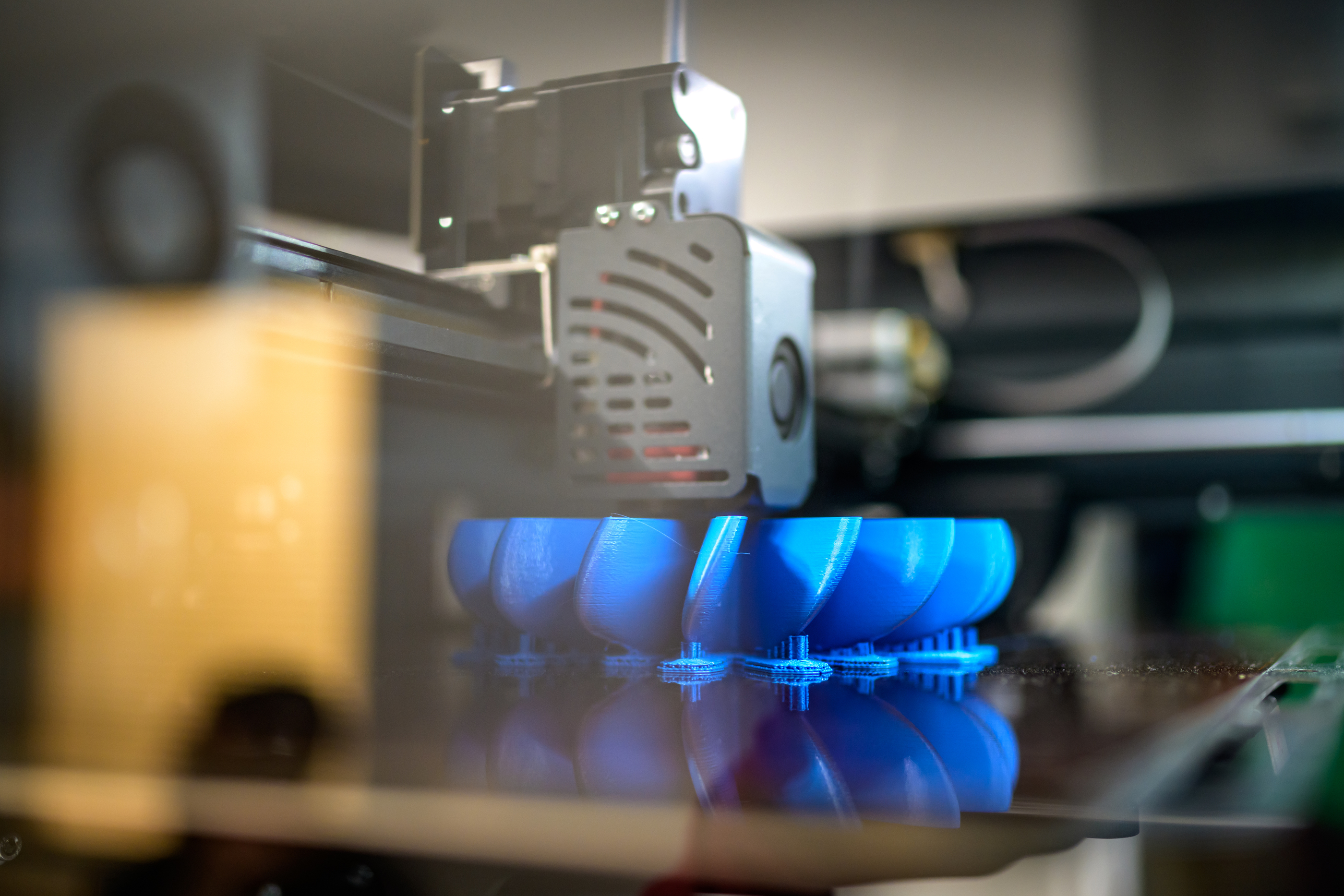

- Markets/industries: beauty & household, cosmetics, packaging, 3D printing, building & construction, automotive, food serviceware.

- End-use applications: utensils, food containers, single-use plastics, prototypes, 3D feedstocks, interior auto parts, decking & railings

Benefits:

- Entropic™ Sustainable Materials have a lower environmental impact through use of bio-based and renewable raw materials

- Entropic™ Sustainable Materials highly filled master-batches stretch further, which requires less material and increases output of finished compounds.

- Entropic™ Sustainable Materials enable lower part mass, which means the weight of final parts can be reduced by up to 15%.

- Entropic™ Sustainable Materials that are PHA-based are marine degradable and degrade more than 10 times faster than conventional bioplastic materials (e.g., standard PHA).

- Entropic™ Sustainable Materials have markedly improved heat resistance (no distortion at temperatures as high as 115°C) when compared to conventional bioplastic materials (e.g., standard PHA or PLA).

- Entropic™ Sustainable Materials contain 30-50% by weight of food-grade material that is commercially used in food and is approved for direct food contact.

- Entropic™ Sustainable Materials are thermally stable and amenable for use in conventional plastics processing equipment and tooling (e.g., injection molding).

Brand Description:

Interfacial introduces its novel and patent-pending Entropic™ Sustainable Materials and looks forward to working with like-minded organizations to preserve our environment for our children, grandchildren and future generations. Entropy, as expressed in the second law of thermodynamics, states that the order of an isolated system cannot increase with time. In layman’s terms, this means everything in the universe that is isolated constantly moves from order to disorder over time. As humans, we battle entropy every day and spend nearly every waking hour fighting entropy in our environment and bodies.Much of our energy and development has been dedicated toward creating materials and products that resist entropic breakdown. Whether it is the paint on our cars, plastic packaging for our foods, or toys for our kids, materials have been created to be extremely durable and resistant to environmental breakdown.

Despite this human ingenuity, there are serious unintended side effects of such miraculous materials science engineering. Our environment is filled with plastics that do not degrade, and it is estimated that our 2,500 active U.S. landfills contain more than 1 billion pounds each of non-degradable plastic waste!

We are entering a phase of human history that in order to sustain life on earth, we must modify our behavior, use less energy, and create less waste. From a materials science perspective, this requires that we deliberately design materials that maintain high functionality while rapidly and harmlessly degrading in the environment.

We have achieved this with Entropic™ Sustainable Materials!

Manufacturer:

Interfacial Consultants LLCWe’re Here to Help

Complete the following fields with your information, as well as a short, detailed description of your request and a NAGASE Specialist will be in touch with you shortly.